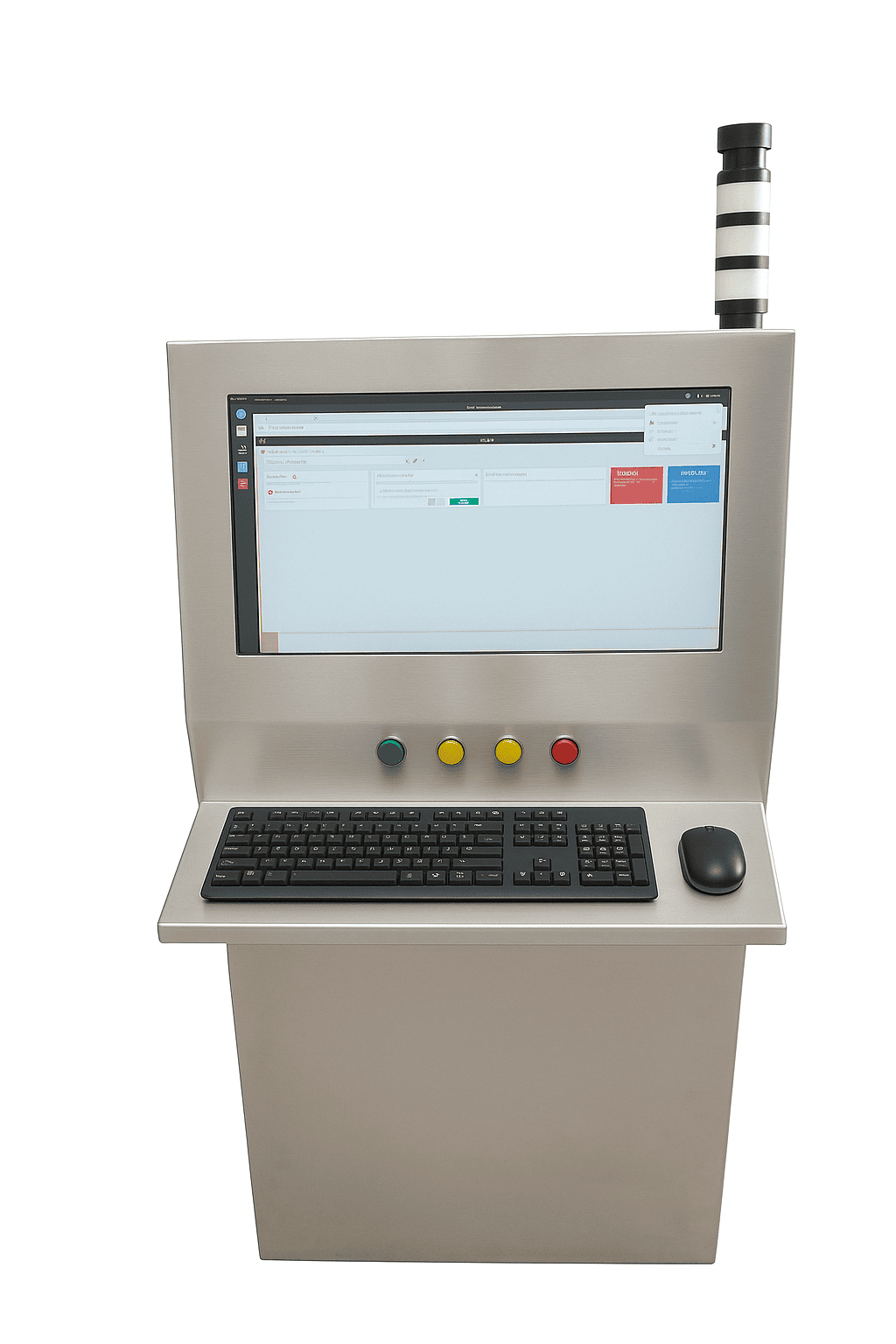

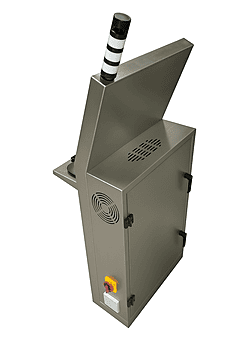

Industrial kiosk with inbuilt PLC control panel

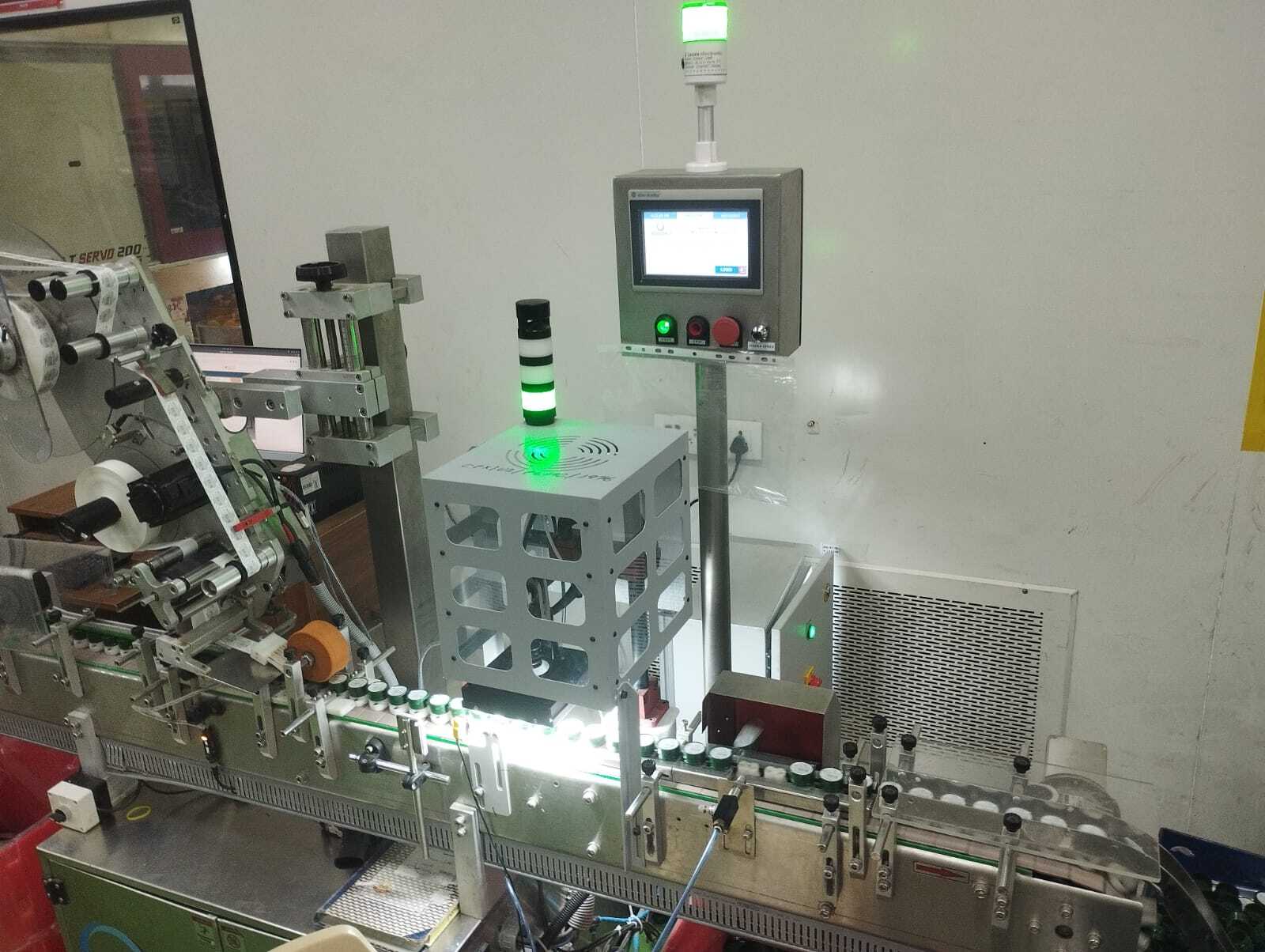

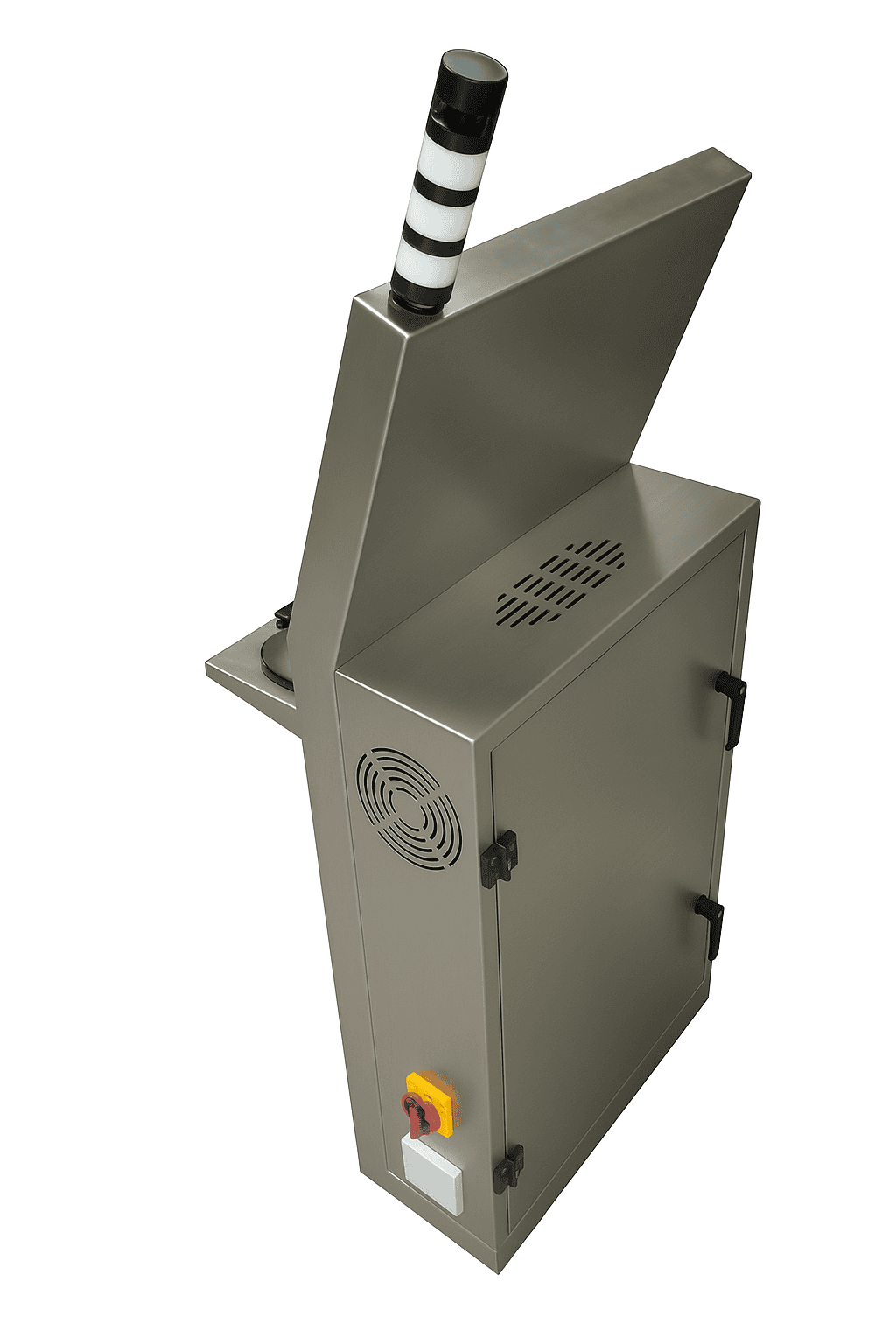

Industrial Kiosk as a part of automation or standalone setup, easily integrable with any system.

I has inbuilt Mitsubishi FX5U PLC control panel . 3 Tier tower lamp with buzzer.

Separate compartment for CPU/GPU and PLC controls.

natural aircooling for PC and forcsed cooling for PLC control

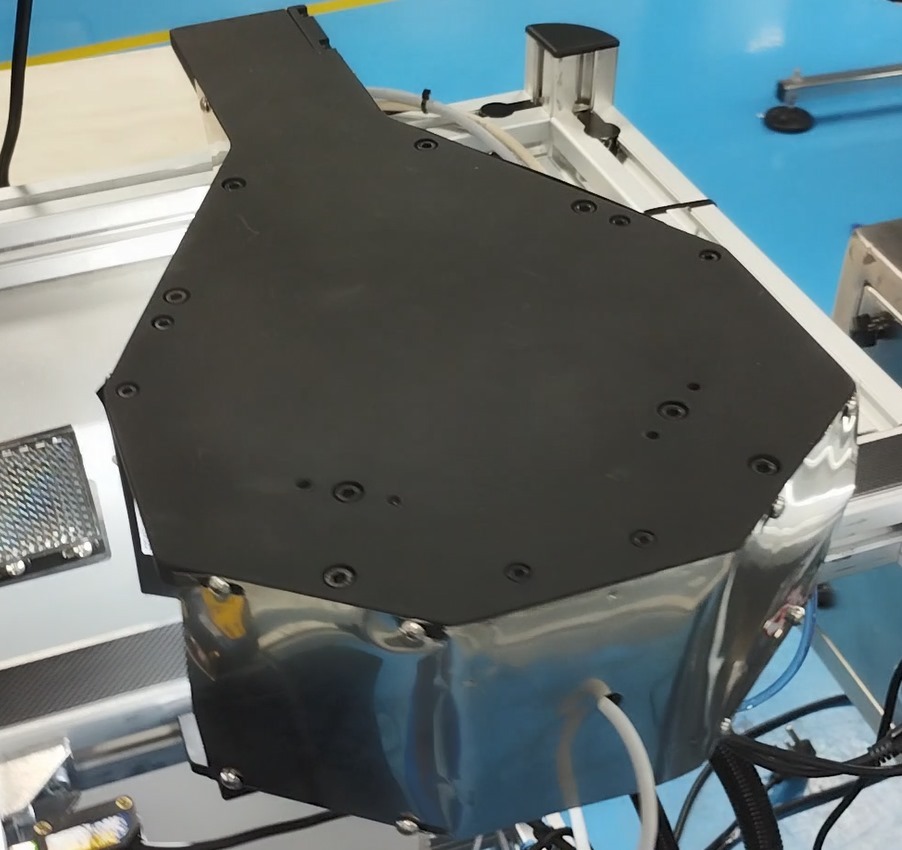

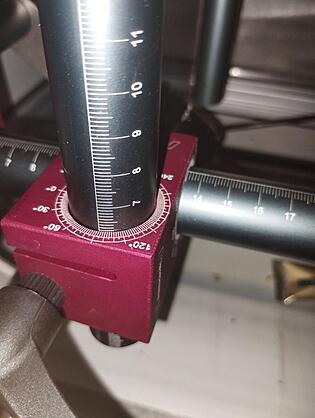

6 -axes camera mounts

For precise positioning and position repeatability of cameras, sensors, light Ignos has a best solution. This unit makes the camera variable in 6 degrees of freedom with linear and rotary motion at each joint.

graduations helps precisely position the camera every time its moved. thereby avoiding reteaching the models

Automatic bottle cleaning, singulation inspection & segregation

Industrial Kiosk as a part of automation or standalone setup, easily integrable with any system.

I has inbuilt Mitsubishi FX5U PLC control panel . 3 Tier tower lamp with buzzer.

Separate compartment for CPU/GPU and PLC controls.

natural aircooling for PC and forcsed cooling for PLC control

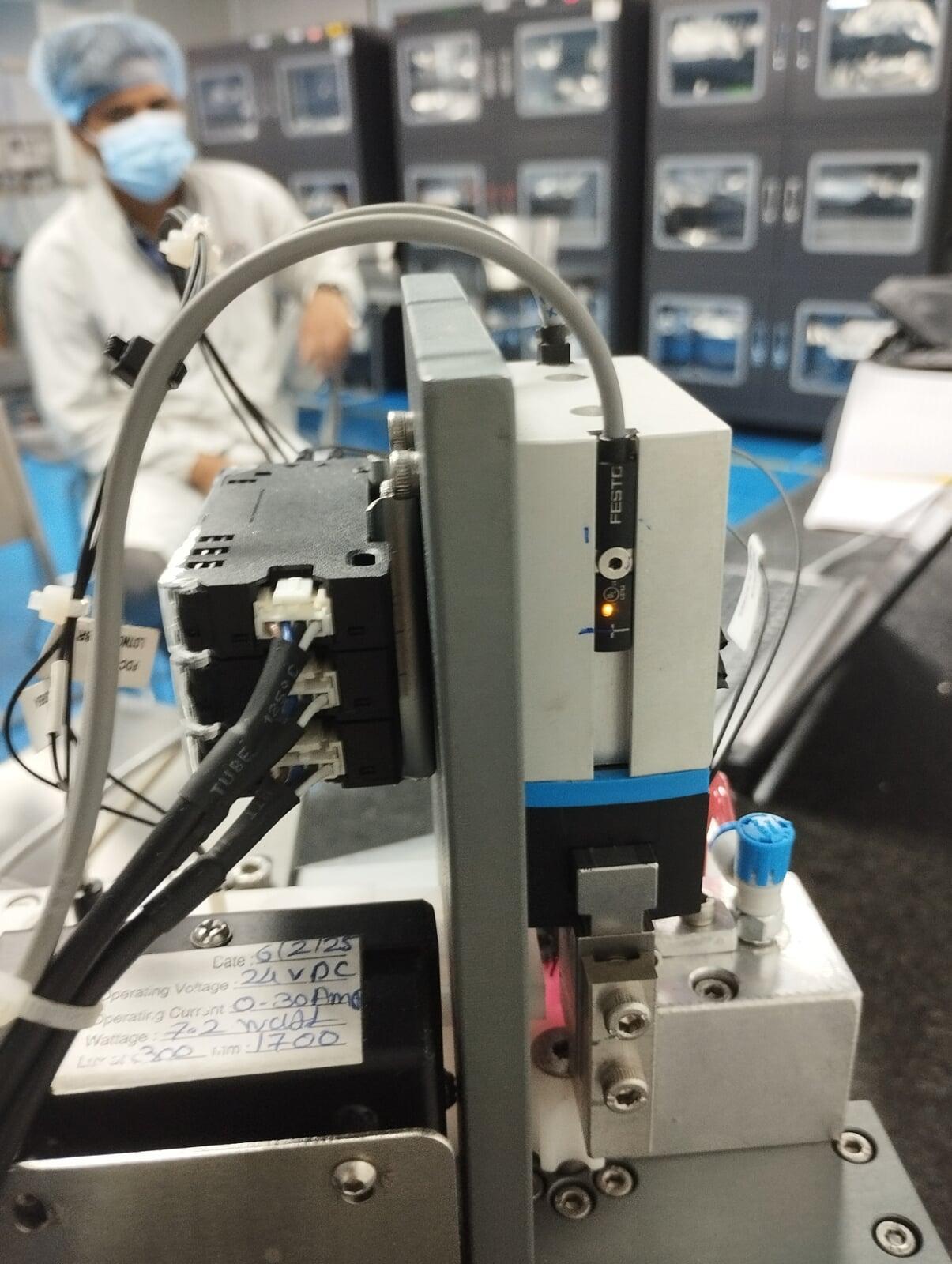

Automated Tube Inspection, Cutting and Segregation

For precise positioning and position repeatability of cameras, sensors, light Ignos has a best solution. This unit makes the camera variable in 6 degrees of freedom with linear and rotary motion at each joint.

graduations helps precisely position the camera every time its moved. thereby avoiding reteaching the models